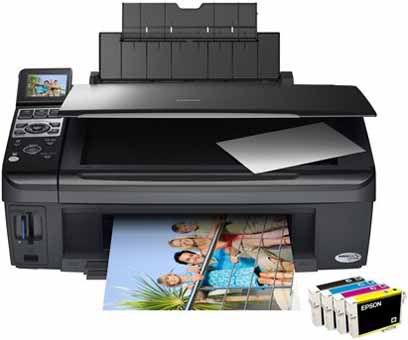

If you have inkjet printer, that so many problem will appear such as, malformed printing result. Cartridge problem. Printer Head problem and other.

This a little tips for Care your CISS inkjet printer.

- The ink bottle must be same height with printer.

- When printing the little hole at bottle ink must be open.

- When you move your printer to other place, the bottle ink must be closed.

- When you refill bottle ink, all cover must be open.

- If printing result is worse. Use Head Cleaning with printer software maintenance.

- Never leave the bottle ink empty.

- Never change ink with other brand.

yes..me too. i have printer epson like that.

ReplyDeleten the first, ink bottle must be same height with printer,

nice post

nice tips.

ReplyDeleteTFS friend.

yeah.. thank's for visit.

ReplyDeleteNice tips.

ReplyDeleteTerima kasih tipsnya.

ReplyDelete