Laser Perforation

Using Laser Technology, perforations of different types and sizes can be produced.

Laser Perforated Serial Number

The ID document serial number is perforated through the substrate with a laser. Typical distinguishing marks are produced: traces of burning round the edges of the holes ;no raised edges round the holes in the substrate (paper) on the back of the perforations ;conical decrease in size of the perforated holes in the book block when viewed from front to back.

Laser Perforated Fine Structures and Design (rip cuts)

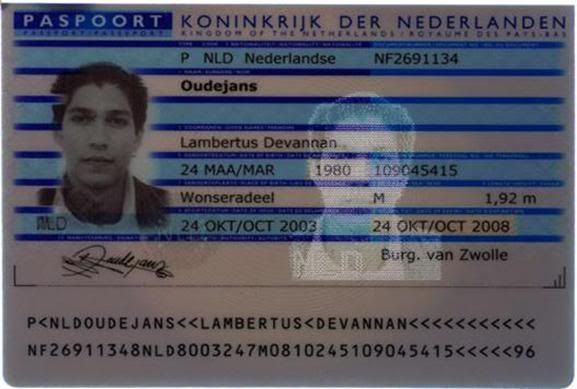

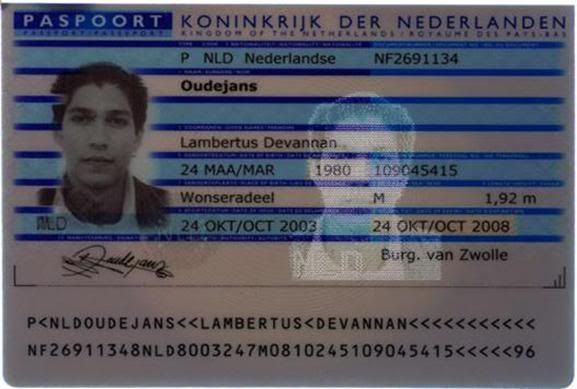

Secondary (ghost) image - laser perforated

Perforation forming a secondary image of the document holder, visible by transmitted light.Examples: Image Perf®, Netherlands and Belgian passports.

Laser perforation with tilting effect

The individual letters of the TLI ® (Tilted Laser Image) are perforated at different angles. The image that can be seen by transmitted light, changes depending on the angle of view.

Source : Click Here

Using Laser Technology, perforations of different types and sizes can be produced.

Laser Perforated Serial Number

The ID document serial number is perforated through the substrate with a laser. Typical distinguishing marks are produced: traces of burning round the edges of the holes ;no raised edges round the holes in the substrate (paper) on the back of the perforations ;conical decrease in size of the perforated holes in the book block when viewed from front to back.

Laser Perforated Fine Structures and Design (rip cuts)

Secondary (ghost) image - laser perforated

Perforation forming a secondary image of the document holder, visible by transmitted light.Examples: Image Perf®, Netherlands and Belgian passports.

Laser perforation with tilting effect

The individual letters of the TLI ® (Tilted Laser Image) are perforated at different angles. The image that can be seen by transmitted light, changes depending on the angle of view.

Source : Click Here

Comments

Post a Comment