MRZ Machine Readable Zone

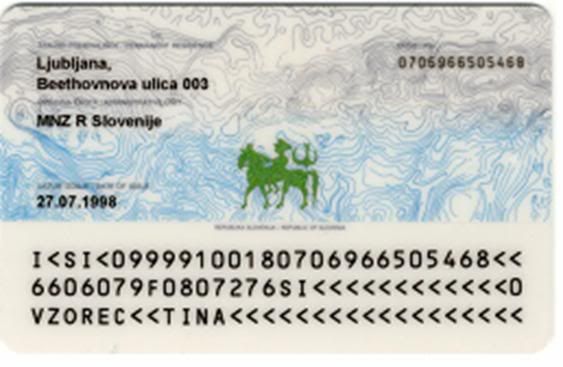

The specifications of Machine Readable Travel Documents (MRTD) are set out in document 9303 of the International Civil Aviation Organisation (ICAO). According to these standards, the biodata page of a MRTD is divided into two different zones:

a Visual Inspection Zone (VIZ) containing the document designation, the holder’s facial image, personal data and data concerning issue and validity.

a Machine Readable Zone (MRZ) containing some of the information from the Visual Inspection Zone in the form of a sequence of alphanumeric characters and the symbol “<”, forming two or three lines. This sequence of characters can be read by document readers in order to facilitate inspections of travel documents (OCR - Optical Character Recognition– fonts). Form of the MRZ: ID1 format (86 x 54 mm): three lines with 30 characters each, situated on the reverse side (verso) of the document. ID2 format (105 x 74 mm): two lines with 36 characters each, situated at the bottom of the biodata page or visa. ID3 format (125 x 88 mm): two lines with 44 characters each, situated at the bottom of the biodata page.

Source : Click Here

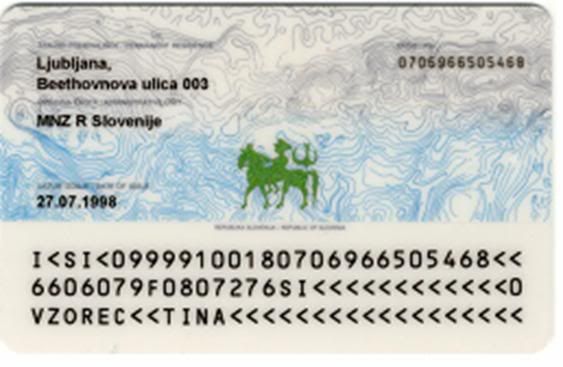

The specifications of Machine Readable Travel Documents (MRTD) are set out in document 9303 of the International Civil Aviation Organisation (ICAO). According to these standards, the biodata page of a MRTD is divided into two different zones:

a Visual Inspection Zone (VIZ) containing the document designation, the holder’s facial image, personal data and data concerning issue and validity.

a Machine Readable Zone (MRZ) containing some of the information from the Visual Inspection Zone in the form of a sequence of alphanumeric characters and the symbol “<”, forming two or three lines. This sequence of characters can be read by document readers in order to facilitate inspections of travel documents (OCR - Optical Character Recognition– fonts). Form of the MRZ: ID1 format (86 x 54 mm): three lines with 30 characters each, situated on the reverse side (verso) of the document. ID2 format (105 x 74 mm): two lines with 36 characters each, situated at the bottom of the biodata page or visa. ID3 format (125 x 88 mm): two lines with 44 characters each, situated at the bottom of the biodata page.

Source : Click Here

Comments

Post a Comment